“General Motors aims to produce 70,000 Bolt models in 2023. The company plans to sell over 400,000 EVs in North America from early 2022 through mid-next year.”

In an announcement, General Motors CEO Mar Barra said the company plans to stop production of its electric Chevrolet Bolt models by the end of 2023.

Also Read, Explorer EV – Ford New Electric Vehicle in European Market

The CEO announced that they would refurbish a suburban Detroit plant. The plant has been producing Chevy Bolts since 2016. The company will prepare it for the production of electric Chevy Silverado and GMC Sierra trucks scheduled for next year.

General Motors aims to produce 70,000 Bolt models in 2023. The company plans to sell over 400,000 EVs in North America from early 2022 through mid-next year.

General Motors pushed the production of Bolt ahead of the Tesla Model 3 in 2016. Bolt and Tesla were thought to be the first long-range electric vehicles (EVs) for mainstream drivers. Their prices start at around $35,000.

But Bolt models never stood on sales expectations of the company, as EV sales remained very low against Tesla. The Bolt also had a hitch recently, as General Motors recalled all of the bolts ever produced because of an issue with a supplier-related battery that used to catch several fires.

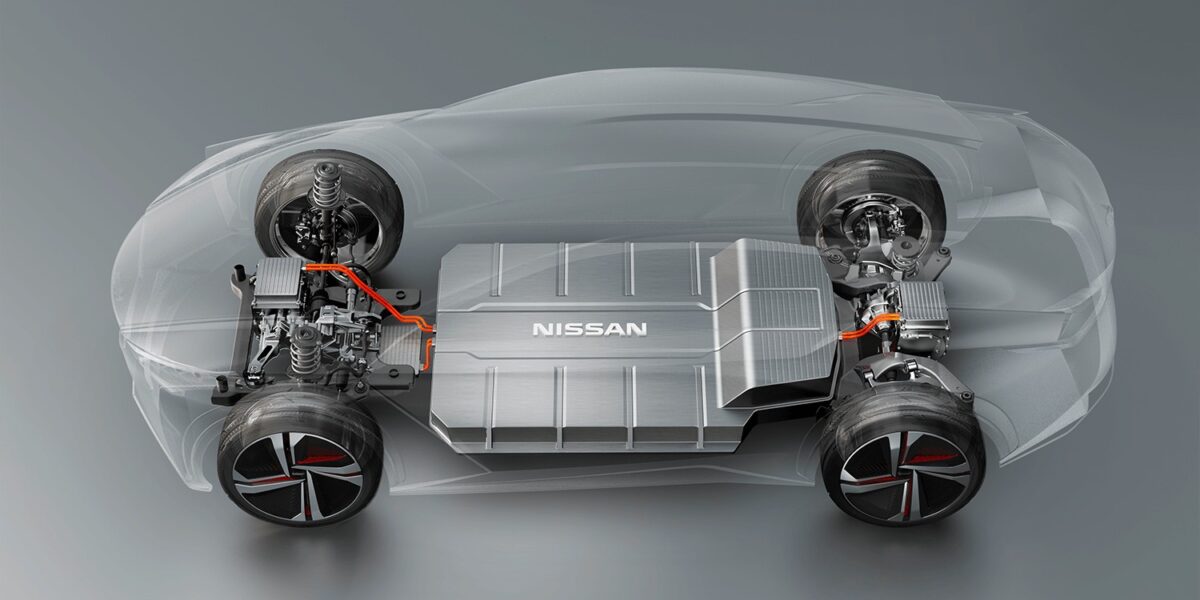

“When the Chevrolet Bolt EV launched, it was a huge technical achievement and the first affordable EV, which set in motion GM’s all-electric future,” Chevy spokesman Cody Williams said in a statement. Chevrolet will launch several new EVs later this year based on the Ultium platform in key segments, including the Silverado EV, Blazer EV, and Equinox EV.”

GM anticipates launching its upcoming electric vehicles more quickly than it has Hummer and Cadillac Lyriq models. The Hummer and Cadillac Lyriq models have been rolling out at a slow pace compared to their traditional vehicles.